Vegetable Sauce Filling Production Line (Romania)

Unlocking the Potential of Our Vegetable Sauce Filling Production Line in Romania

In the world of food processing, efficiency and precision are paramount. For manufacturers looking to enhance their production capabilities, our Sauce Filling Production Line provides manufacturers with an affordable solution.

“The Vegetable Sauce Filling Production Line represents a significant advancement in the food processing industry, offering Romanian manufacturers the tools they need to enhance efficiency, reduce costs, and improve product quality. By investing in these automated systems, manufacturers can position themselves as leaders in the sauce market, meeting the growing demands of consumers both locally and globally.”

The Rise of Automated Sauce Filling Lines

The demand for sauces—whether it's chili, tomato, or vegetable-based—continues to grow globally. As consumers seek out diverse flavors, manufacturers must adapt by investing in versatile and efficient production systems. The Vegetable Sauce Filling Production Line is designed to meet this demand, providing a fully automated solution that streamlines the entire process from filling to packaging.

Key Features of the Vegetable Sauce Filling Production Line

High-Precision Filling: Utilizing advanced servo motor control, these production lines ensure each bottle is filled with precision, maintaining an error rate as low as ±1%. This is crucial for maintaining consistency in product quality, especially for sauces of varying viscosities.

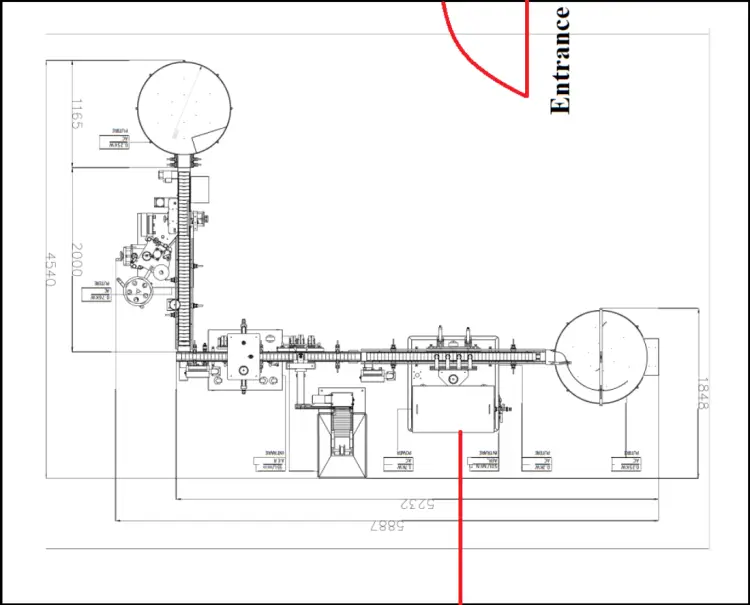

Integrated System: The production line integrates filling, capping, and labeling functions into one seamless system. This reduces the need for manual labor, minimizes errors, and increases overall production efficiency.

Adaptability: With the ability to handle various bottle types and sizes. This flexibility is vital for manufacturers producing multiple sauce varieties.

Hygienic Design: Meeting the highest hygiene standards, the Sauce Filling Production Line is easy to clean and maintain, ensuring that all products are safe for consumption.

Benefits of Implementing Automated Sauce Filling Systems

Increased Efficiency: By automating the filling, capping, and labeling processes, manufacturers can significantly boost their production speed. This leads to higher output rates and the ability to meet growing consumer demands.

Cost Reduction: Automation reduces the need for manual labor, cutting down on labor costs and minimizing human errors. This translates to cost savings in the long run.

Enhanced Product Quality: With precise filling and consistent packaging, manufacturers can ensure that every bottle of sauce meets high-quality standards, enhancing brand reputation and customer satisfaction.

Scalability: As demand for sauces grows, these production lines offer scalability, allowing manufacturers to easily increase their production capacity without major overhauls.

Sectors Benefiting from Automated Sauce Filling

Food Industry: From ketchup to gourmet sauces, the food industry can greatly benefit from the efficiency and precision offered by these production lines.

Agriculture: With Romania's rich agricultural resources, manufacturers can produce a variety of vegetable-based sauces, tapping into the growing trend of plant-based foods.

Cosmetics and Daily Chemicals: Beyond food, these production lines can be adapted for use in other sectors, such as cosmetics and chemicals, where precise filling and packaging are equally important.