| Model | FLS-10 | FLS-30 | FLS-100 | FLS-500 | FLS-1000 |

|---|---|---|---|---|---|

| Voltage | 220V 50/60HZ | ||||

| Power | 1.72KW | ||||

| Filling range | 1-10g | 10-30g | 30-100g | 100-500g | 100-1000g |

| Hopper volume | 20L | ||||

| Dimension | L:220xW:45xH:187cm | ||||

| Weight | 175kgs | ||||

Product Overview

The FLS-1000 is a fully integrated powder filling line designed for high-accuracy packaging of various dry powders including toner, protein supplements, spices (pepper), and other fine to granular dry products. This complete automatic powder filling machine system combines precision weighing, automated filling, and seamless conveying into one efficient production line. Engineered to handle the challenges of dry powder filling, the FLS-1000 minimizes dust, prevents cross-contamination, and ensures consistent fill weights with exceptional accuracy. From bulk material feeding to sealed packaging output, this comprehensive weigh filling machine solution maximizes productivity while maintaining the highest quality standards for manufacturers in the chemical, food, pharmaceutical, and nutraceutical industries.

Features

High-Precision Filling System

Complete Automated Powder Filling Line

Versatile Product Handling

Intelligent Control System

Hygienic & Durable Construction

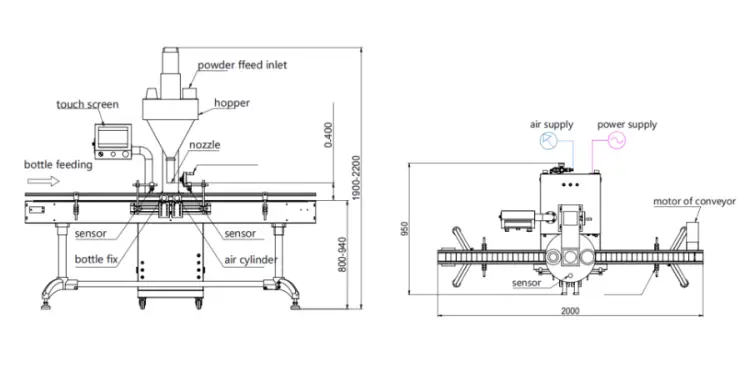

Drawings

Technical Parameters

Auto Auger screw powder filling line | |||||

Model | FLS-10 | FLS-30 | FLS-100 | FLS-500 | FLS-1000 |

Voltage | 220V 50/60HZ | ||||

Power | 1.72KW | ||||

Accuracy | About±1% | ||||

Filling range | 1-10g | 10-30g | 30-100g | 100-500g | 100-1000g |

Capacity | 10g | 10g | 100g | 300g | 300g |

790BPH | 990BPH | 1320BPH | 550BPH | 825BPH | |

Hopper volume | 20L | ||||

Dimension | L:220xW:45xH:187cm | ||||

Weight | 175kgs | ||||

Application

The FLS-1000 dry powder filling machine line is engineered for diverse industries requiring precise, hygienic powder packaging:

Chemical & Industrial Products:

Printer toner and developer powder

Detergent powder and cleaning compounds

Metal powders and industrial additives

Pigments and dye powders

Food & Beverage:

Protein powder and nutritional supplements

Spices (pepper, paprika, cumin, etc.)

Flour, baking powder, and dry mixes

Instant beverage powders and milk powder

Pharmaceutical & Nutraceutical:

Medicinal powders and formulations

Vitamin and mineral supplements

Herbal powder and traditional medicines

Powdered antibiotics and pharmaceuticals

Agriculture & Animal Feed:

Feed additives and premixes

Pesticide and fertilizer powders

Seed treatment powders

Cosmetics & Personal Care:

Talcum powder and body powder

Makeup powder and pigments

Dry shampoo and cosmetic powders

The FLS-1000 line can be customized with additional modules such as nitrogen flushing for oxygen-sensitive products, metal detection, checkweighing, labeling, and cartoning to create a complete end-to-end packaging solution.