Rotary pumps are a type of positive displacement pump that uses rotating elements to trap a fixed volume of fluid and move it from the suction to the discharge side. They are valued for their ability to deliver a constant flow rate regardless of pressure and to handle high-viscosity liquids efficiently.

Besacker combines lobe pumps/gear pumps with filling systems and servo motors to create a filling machine suitable for paste filling.

|

|

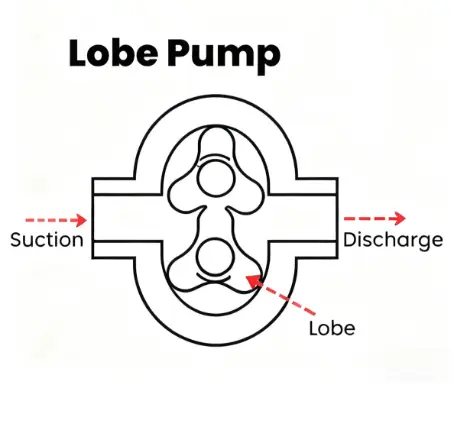

Lobe pumps

Pumping viscous liquids, slurries, and delicate or shear-sensitive fluids, such as food products, pharmaceuticals, and chemicals. Their large pumping cavities allow them to handle large solids without damage. Best for: Pumping viscous liquids, slurries, and delicate or shear-sensitive fluids, such as food products, pharmaceuticals, and chemicals. Their large pumping cavities allow them to handle large solids without damage.

Work air pressure | 0.4-0.6Mpa |

Power supply | 220V, 50HZ/60HZ, 0.8KW |

Hopper volume | 40L |

Filling accuracy | ±1% |

Rotor pump flow rate | 20L/min |

Capacity | 300-2500 bph |

|

Tri-lobe Rotors A common, general-purpose design that is good for clean mediums and can handle a higher volume than bi-wing models. |

|

Bi-wing Rotors A two-lobe design that provides a smooth, consistent flow and is suitable for viscous fluids with solids. |

|

Two-lobe Rotors This type is suitable for liquids with low hardness particles. |

|

Multi-lobe Rotors This offer increased stability and accuracy, with the ability to be used for metering when the number of impellers is high. |

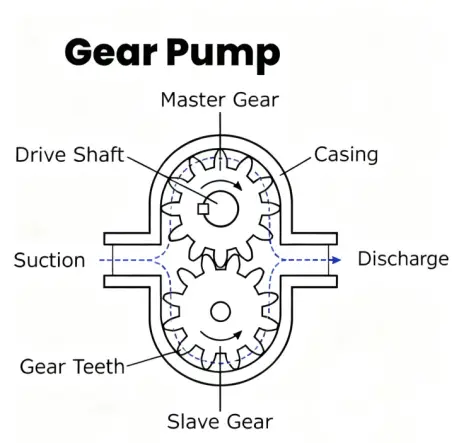

Gear pumps

Gear pumps use the meshing action of rotating gears to pump fluid. Best for: Pumping viscous liquids like oils, resins, and paints. They are also suitable for high-pressure applications.

Work air pressure | 0.4-0.6Mpa |

Power supply | 220V, 50HZ/60HZ, 0.8KW |

Hopper volume | 30L |

Filling accuracy | ±1% |

Rotor pump flow rate | 15ML/rev |

Capacity | 35L/min |

|

Gear Rotors This type is suitable for liquids with low hardness particles. |

Feature of rotary pumps:

Gentle Rotor Pump Action: Ideal for products with chunks, fibers, or high viscosity; delivers a smooth, non-pulsating flow that preserves product integrity.

Exceptional Accuracy: Provides highly repeatable fill volumes for both thick and thin liquids, minimizing product giveaway and ensuring cost control.

Hygienic & Easy to Clean: Constructed with stainless steel (SS304/316) contact parts and designed with quick-disassembly capabilities for fast changeover and cleaning.

User-Friendly PLC Control: An intuitive touchscreen interface allows for easy setup, storage of filling parameters.