Description:

This advanced six-head servo-piston filler delivers unparalleled accuracy for liquid and semi-liquid products. Achieving filling tolerances within ±1%, it handles volumes from 100ml to 1000ml with effortless recipe changes through its intuitive touchscreen interface. The sanitary stainless steel construction, simple auto-cleaning system, and servo-driven precision make it ideal for pharmaceuticals, food, and cosmetics. Engineered for high-output environments, it seamlessly integrates into automated lines, ensuring maximum productivity with minimal waste.

Feature:

1. Servo Drive System

The delicate servo system controls the filling amount through precise piston strokes, providing high filling accuracy. With the vertical movement of the filling piston provides long term energy saving and also effectively reduces machine load rate.

2. Tool-Free Adjustment

Adjustments can be made through the PLC, giving users a fast and efficient result. The delicate servo control system design provides options for surface layer liquid filling, bottom layer liquid filling, and bottle neck (opening) filling accordingly with different types of liquids.

3. Different filling range optional

50-500ml, 100-1000ml, 500-5000ml. Filling nozzles can be customized with 4 /6 /8 filling heads with anti-drop type, different size as your request.

Technical Parameter:

Filling speed | l 30–70 bottles/min (Depending on materials and bottle size) |

Power supply | l About 3kw |

Driver | l Servo motor |

Filling pump | l Piston pump |

Hopper volume | l 170L |

Filling head | l 6 heads (Can be customized) |

Voltage | l 220V/380V |

Air pressure | l 0.4-0.7 Mpa |

Air consumption | l 100L/min |

Filling range | l 100-1000ml |

Filling accuracy | l ≤1% |

Speed of conveyor belt | l 0-12.5m/min |

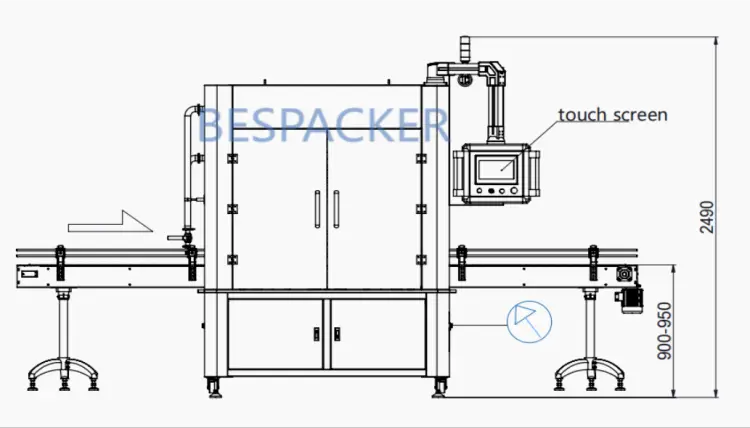

Machine dimension | l L4000 X W1265 X H2490 mm |

Main configuration list:

No. | Name | Brands |

1 | PLC | Delta |

2 | Touch Screen | Delta |

3 | Remote control module | Delta |

4 | Servo motor for filling system | Delta |

5 | Lift-down servo motor | Delta |

6 | Servo motor for conveyor belt | Xiushi |

7 | Frequency converter | Delta |

8 | Power switch | Siemens |

9 | Intermediate relay | Siemens |

10 | Circuit breaker | Siemens |

11 | AC contactor | Siemens |

12 | Solenoid valve | Airtac |

13 | Air cylinder | Airtac |

Photo Details:

| Customize the bottle stopping system according to different bottles. |

| Servo motor control, easy to adjust the volume, just need to input the volume needed in touch screen. |

Machine Dimension: