Machine speed | Around 800-1600 cups/hour |

Power supply and consumption | 380V 2KW |

Pressed Air Supply | 0.6-0.8 Mpa |

Heating temperature | 0-400℃ |

Machine dimension | 1000*1000*1500mm(depends) |

Contact parts material | SS304 |

Weight | 350KG(depends) |

Our Rotary Cup Sealing Machine is a high-speed, fully automated cup filling sealing machine designed for sealing cups, jars, and containers across the food, dairy, and FMCG industries. Engineered for precision and reliability, it seamlessly integrates into production lines to deliver consistent, airtight seals that extend product shelf life and enhance presentation.

With its rotary indexing mechanism, the machine operates with continuous motion, maximizing output while minimizing space requirements—ideal for high-volume production environments like yogurt, desserts, pudding, and dairy product packaging.

Main configuration list:

Name | Manufacturer |

PLC | Delta |

Touch screen | Delta |

Motor | Xiushi (made in china) |

Pneumatic cylinder | Maier (made in china) |

Electrical parts | CHNT |

Switch | Schneider |

Power parts | Mean Well |

Key Features & Advantages

High-Speed Rotary Design

A continuous rotary motion system enables high-speed operation (up to 800-1,600 cups/hour), significantly boosting production efficiency compared to linear machines. It is perfectly suited as a versatile plastic cup sealing machine.Precision Sealing & Consistency

Equipped with sealing heads and precise temperature control, it ensures uniform, hermetic seals every time, critical for product freshness and safety.Hygienic & Easy Maintenance

Constructed with food-grade stainless steel (SS304/SS316) and featuring a smooth, crevice-free design, it meets stringent hygiene standards (e.g., EHEDG, GMP) and is easy to clean.Intelligent Control & Monitoring

A user-friendly PLC-based HMI touch screen allows for easy parameter setup, real-time monitoring of production data, diagnostics, and seamless integration with upstream/downstream equipment.Robust & Durable Construction

Built with high-quality components and a sturdy frame, the machine ensures long-term reliability, low maintenance costs, and stable performance in demanding 24/7 operations.

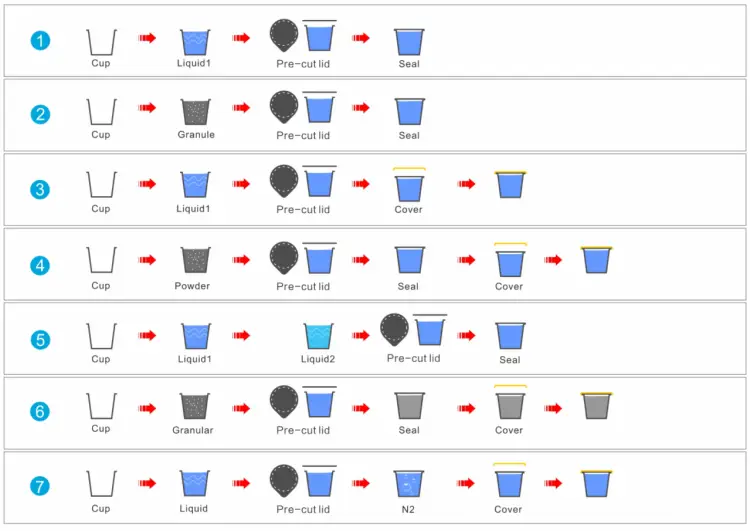

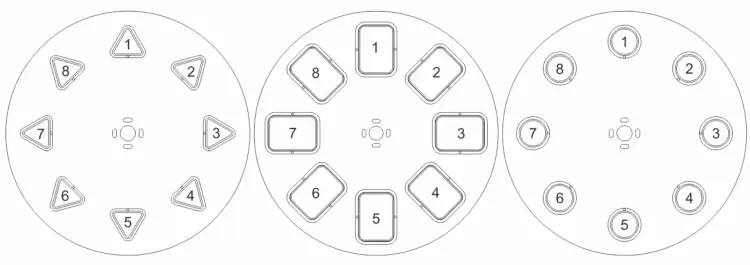

Drawings

Customized aluminum plate

Applications

This versatile sealer is perfect for a wide range of products requiring secure cup packaging:

Dairy Products: Yogurt, cream, cottage cheese, fresh cheese. It is an ideal yogurt cup sealing machine for high-capacity lines.

Desserts & Snacks: Pudding, jelly, mousse, fruit cups, ice cream.

Ready-to-Eat Foods: Salads, dips, sauces, condiments.

Other: Packaging for pharmaceuticals, cosmetics, and industrial parts in cup-type containers.

Why Choose Our Rotary Sealer?

Choosing our machine means investing in peak line efficiency, reduced waste, and superior seal quality. Our focus on durable engineering, ease of use, and comprehensive after-sales support ensures you get a packaging solution that not only meets but exceeds your productivity goals.

Ready to optimize your packaging line? Contact our engineering team today for a detailed quotation or to schedule a live product demonstration tailored to your specific containers and outputs.