Overview:

The Compact filling and capping monoblocks are the ideal solution for pharma and cosmetic factories with limited space. The small scale of the machine also participates in savings from the construction of clean spaces. Based on the materials and packaging, we can customize different systems to suit your product.

Description:

This roll-on deodorant mono-block machine incorporates German technology, developed and introduced by our company. It integrates mechanical, pneumatic, and automated systems, and is characterized by its high degree of automation, excellent stability, and strong adaptability, resulting in high output. Specifically engineered for non-standard products, the machine also maintains full compliance with GMP standards for pharmaceutical production.

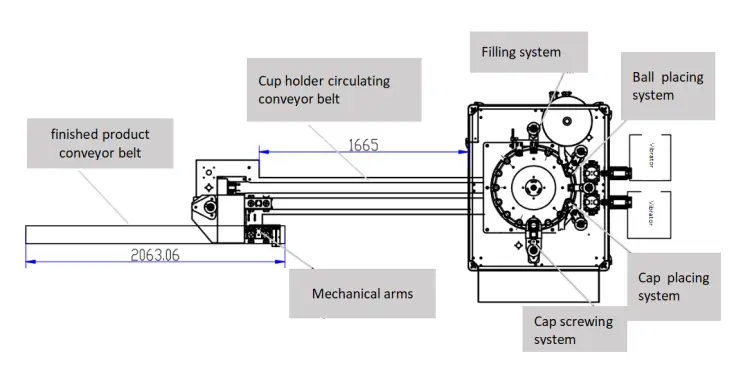

Layout and dimension:

Features:

PLC control & convenient operation.

Variable frequency control, adjustable production speed, and automatic counting.

Automatic shutdown function: if there is no bottle, then machine will stop filling and capping.

High precision cam indexing control, precise positioning.

Made of SUS304 and 316L stainless steel, fully compliant with GMP requirements.

Technical Parameter:

Filling volume | l 10 - 100ml |

Power supply | l 220V/50HZ |

Filling Accuracy | l ≤ 1% |

Filling Speed | l 30-40 BPM |

Power | l 3.5 kw |

Other applications: