Product Overview

The XKNF-30 is a fully automatic, high-precision tube filling and sealing machine designed for efficient packaging of viscous and semi-viscous products. Engineered to handle both plastic tubes and glass tubes with exceptional reliability, it is the ideal solution for manufacturers of hand cream, toothpaste, ointments, gels, and cosmetic lotions. Combining the functions of a precision tube filler and a robust tube sealer in one integrated system, it ensures airtight, professional packaging that enhances product shelf life and brand presentation. Its automated operation maximizes production efficiency while minimizing manual intervention and product waste.

Features

High-Precision Filling System

Reliable and Adjustable Sealing

Fully Automated Operation

Hygienic & Easy Maintenance Design

Versatile and Flexible

Robust Construction

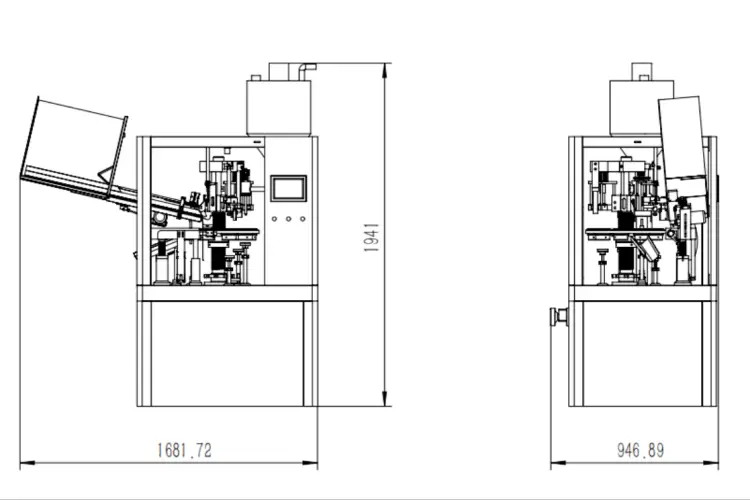

Drawings

Technical Parameters

ITEMS | BRAND | ORIGIN |

PLC | DELTA | TAIWAN |

Frequency Changer | DELTA | TAIWAN |

Touch Screen | EVIEW | TAIWAN |

Encoder | OMRON | JAPAN |

Hot Air Generator | Leister | Switzerland |

Thermometer MODE | DELTA | TAIWAN |

Proximity switch | SICK | GERMANY |

Color Code Sensor | PANASONIC | JAPAN |

Air Pressure Control System | OMRON | JAPAN |

Change Speed Motor | WANNAN | CHINA |

Main Pneumatic component | AIRTAC | TAIWAN |

Air-break switch | CHNT | CHINA |

Emergency Swift | Schneider | FRANCE |

Power switch | Schneider | FRANCE |

Power lock | Schneider | FRANCE |

Power indicator | Schneider | FRANCE |

Ac contactor | Schneider | FRANCE |

Material contact parts | 316L Stainless Steel | CHINA |

Machine Structure | 304 Stainless steel | CHINA |

Filling range | l 5-250ml (5-25 ml、25-75ml、75-250ml) |

Diameter of flexible tubes | l 13-50mm |

Length of flexible tubes | l 50-220mm |

Filling accuracy | l ≤±1% |

Tail sealing method | l Heating with a hot air gun |

Production capacity | l 30-40/min |

Power of the main motor | l 1.5Kw |

Power of hot sealing | l 3.5KW |

Working air pressure | l 0.8MPa |

Weight | l 850kg |

Overall dimensions | l 1700mm×1000mm×2000mm |

Application

The XKNF-30 is widely used across industries that require reliable tube packaging for semi-solid and viscous products:

Cosmetics & Personal Care: Hand cream, facial creams, lotions, body butter, hair gels, styling wax, masks.

Oral & Dental Care: Toothpaste, teeth whitening gel, mouth ulcer gel, dental adhesives.

Pharmaceutical & OTC: Topical ointments, analgesic creams, antiseptic gels, medicated balms.

Household & Industrial: Adhesives (e.g., silicone sealants), lubricants, polishing compounds, shoe polish, artists' paints.

Food: Condiments (e.g., mayonnaise, mustard in tubes), cake icing, edible pastes.

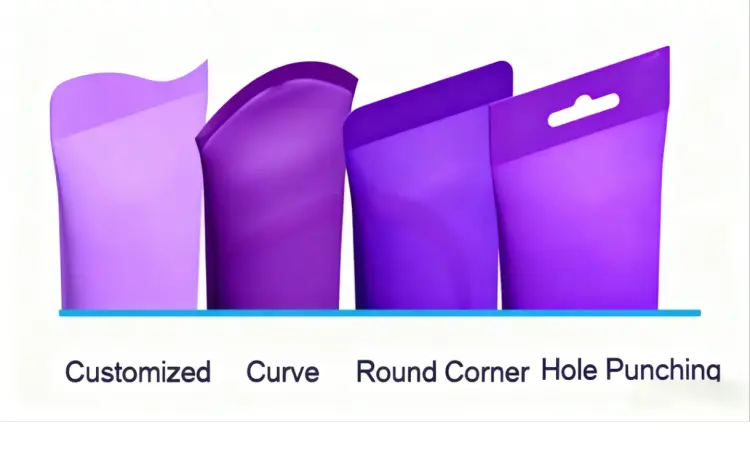

Sealing Pattern: