Tube Packaging Solution

The Ultimate Guide to Tube Fillers and Tube Packaging Machines: Enhancing Efficiency in Tube Filling and Sealing

In today’s fast-paced manufacturing landscape, efficiency, precision, and hygiene are paramount—especially in industries like pharmaceuticals, cosmetics, food, and chemicals. Tube fillers and tube packaging machines have revolutionized how companies fill and seal products in alu tubes, laminated tubes, and plastic tubes. Whether you’re producing creams, ointments, toothpaste, or adhesives, selecting the right tube filling and sealing machine can significantly impact your production quality and output.

This comprehensive guide delves into the world of tube fillers and tube packaging machines, highlighting their features, benefits, and applications. We’ll explore how these machines handle different tube materials and why they are essential for modern packaging processes.

What is a Tube Filler and Tube Packaging Machine?

A tube filler or tube packaging machine is specialized equipment designed to fill tubes with various products and seal them efficiently. These machines automate the process of filling viscous, semi-viscous, or liquid products into tubes made of plastic, aluminum (alu tube), or laminated materials, followed by sealing and coding.

The integration of tube filling and sealing machines in production lines enhances productivity by reducing manual labor, minimizing errors, and ensuring consistent product quality.

Types of Tubes Handled by Tube Filling Machines

Alu Tube (Aluminum Tube): Commonly used for pharmaceuticals, cosmetics, and food products, aluminum tubes provide excellent protection against light, air, and moisture, preserving product integrity.

Laminated Tube: Made from multiple layers of plastic and aluminum foil, laminated tubes combine flexibility with barrier protection, widely used in cosmetics and pharmaceuticals.

Plastic Tube: Flexible and lightweight, plastic tubes are favored for products like creams, gels, and pastes, offering cost-effectiveness and ease of use.

Key Features of Modern Tube Filling and Sealing Machines

1. Automatic Tube Feeding and Orientation

Tubes are automatically loaded from a hopper or magazine.

Orientation mechanisms ensure tubes are correctly positioned for filling and sealing.

Photoelectric sensors detect tube presence to prevent filling errors.

2. Precision Filling Systems

Filling volumes adjustable from as low as 5 ml up to 500 ml depending on the model.

Suitable for high-viscosity materials (creams, ointments) and liquids.

Heated hoppers and mixing systems maintain product consistency and temperature.

3. Advanced Sealing Techniques

Hot Air Sealing: Common for plastic and laminated tubes, providing a clean and reliable seal.

Ultrasonic Sealing: Offers molecular fusion without adhesives, ideal for transparent and aesthetically pleasing seals.

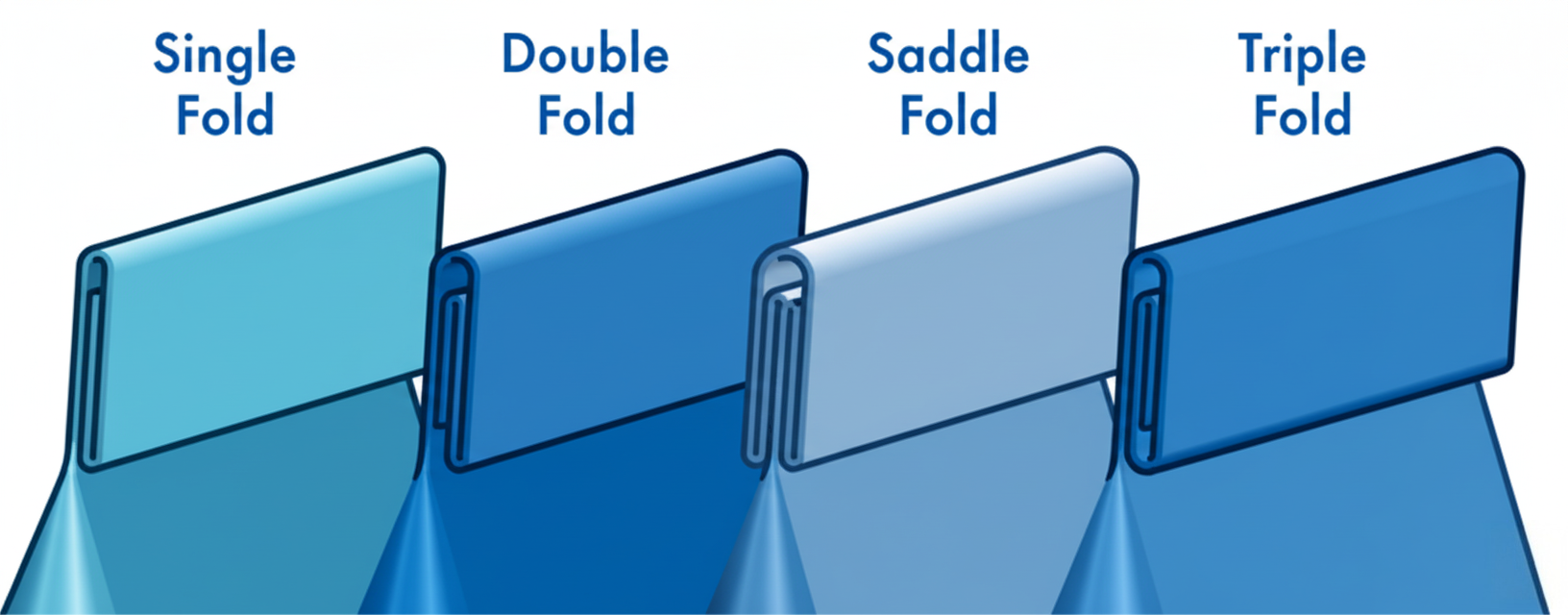

Folding and Crimping: Used primarily for alu tubes, including double and saddle folds for secure closure.

4. User-Friendly Control Systems

Touchscreen interfaces with PLC control for easy operation.

Real-time monitoring with alarms for no tube/no fill conditions.

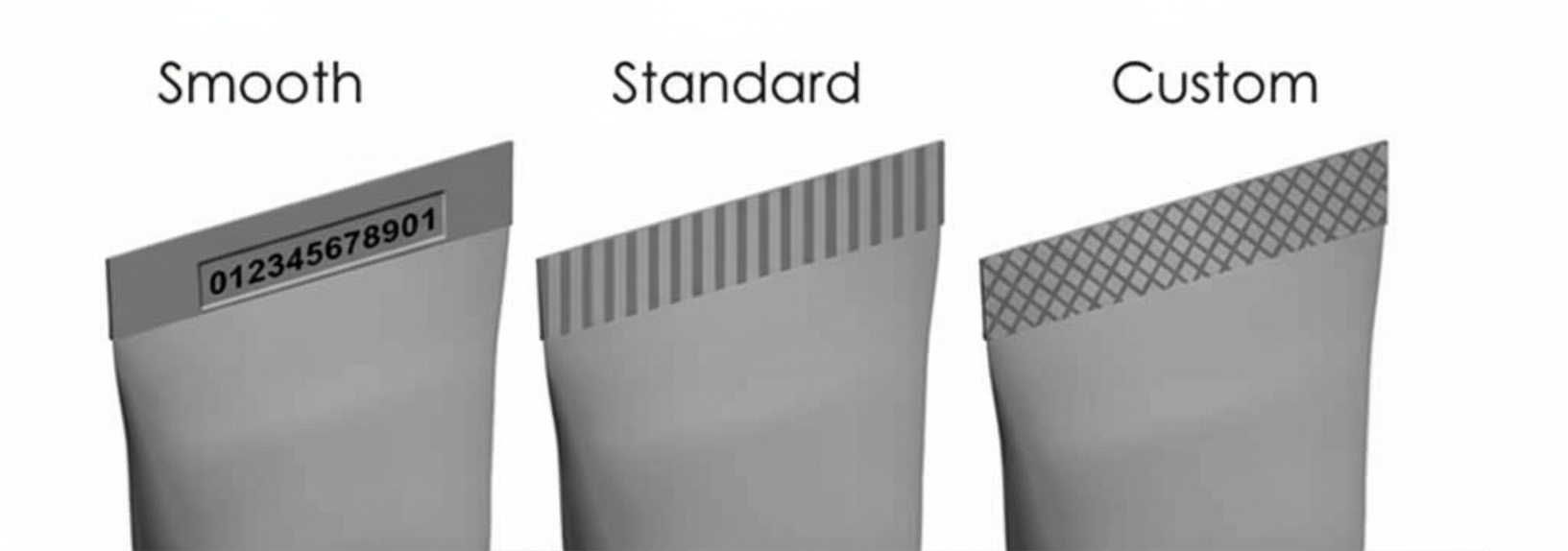

Programmable settings for batch numbering, coding, and sealing parameters.

5. Hygienic and Durable Construction

Stainless steel (AISI 304 and AISI 316) wetted parts ensure corrosion resistance and easy cleaning.

GMP-compliant designs suitable for sterile environments, especially in pharmaceuticals.

Applications Across Industries

Tube filling and sealing machines are indispensable in several sectors:

Pharmaceuticals: Filling ointments, creams, and gels with strict hygiene and precision.

Cosmetics: Packaging lotions, shampoos, and skincare products efficiently.

Food Industry: Filling pastes, sauces, and condiments like mayonnaise and chocolate.

Chemicals: Handling adhesives, sealants, and pesticides with safe and accurate filling.

Investing in a high-quality tube filler and tube packaging machine is critical for businesses aiming to enhance their production efficiency, product quality, and operational hygiene. Whether working with alu tubes, laminated tubes, or plastic tubes, modern tube filling and sealing machines offer versatile, precise, and user-friendly solutions tailored to diverse industry needs.

Ready to upgrade your packaging line? Explore the latest tube filling and sealing machines from trusted manufacturers to find the perfect fit for your production goals. Efficient tube filling isn’t just about speed—it’s about delivering consistent quality that your customers trust.